An O-ring kit is essential for sealing and maintaining various mechanical systems, offering a range of O-rings suitable for different applications.

An O-ring kit is an essential tool for sealing and maintaining various mechanical systems, providing a range of O-rings suitable for different applications.

These kits are crucial for ensuring a proper seal, preventing leaks, and enhancing the longevity of equipment.

Read on to discover the importance of O-rings, how to choose the right kit, installation tips, and more.

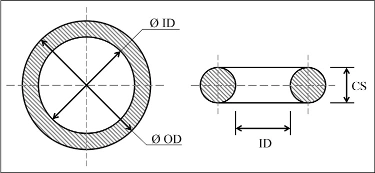

An O-ring is a loop of elastomer with a circular cross-section designed to prevent the passage of liquids or gases.

It functions by sitting in a groove and being compressed between two or more parts to create a seal.

O-rings are widely used in various industries, including automotive, aerospace, and plumbing, due to their effectiveness and ease of use.

Choosing the right material is crucial when using O-rings. Common materials include nitrile rubber (NBR), silicone, fluorocarbon (Viton), and EPDM.

Each material has specific properties that make it suitable for different applications, such as resistance to heat, chemicals, or weathering.

Ensure the O-ring kit contains a variety of sizes to match the requirements of your applications. The correct size ensures a proper fit and optimal sealing performance.

Consider the types of fluids and the temperature range your O-rings will be exposed to.

For example, fluorocarbon O-rings (Viton) are excellent for high-temperature applications, while nitrile rubber (NBR) is suitable for petroleum-based oils and fuels.

Look for O-ring kits that comply with industry standards such as AS568, ISO 3601, or DIN. Compliance with these standards ensures the O-rings’ reliability and quality.

Before installing an O-ring, ensure all surfaces are clean and free from debris or contaminants. This prevents damage to the O-ring and ensures a proper seal.

Using a compatible lubricant helps in the installation process, reducing friction and preventing the O-ring from twisting or tearing.

Do not stretch the O-ring excessively during installation, as this can compromise its sealing capability. Stretch just enough to fit it over the groove or fitting.

Place the O-ring correctly in the groove, ensuring it is not twisted or misaligned. Proper alignment is crucial for effective sealing.

Aocheng is a leading manufacturer of high-quality O-ring kits, providing reliable sealing solutions for various industries.

With over two decades of experience, Aocheng offers a wide range of O-rings made from different materials, including nitrile rubber, silicone, and fluorocarbon.

Their products meet international standards and are known for their durability and performance.

For high-quality O-ring kits that meet your specific needs, contact Aocheng today and experience superior sealing solutions.