Explore the benefits of using lube meters for accurate lubrication, their functionality, and key industrial applications.

Lube meters measure and dispense precise amounts of oil or grease to keep equipment properly lubricated. Accurate dosing prevents over or under-greasing bearings, while convenient operation streamlines preventative maintenance routines.

The Aocheng exclusively utilizes high-quality sources, such as peer-reviewed studies, to substantiate the facts in our articles. Our dedication to accuracy and reliability guarantees that readers obtain well-researched and trustworthy information.

Let’s explore lube meter functionality, usage, and key applications.

Lube meters work much like fuel pumps – just for delivering oil instead of gasoline. An internal piston displaces precise grease amounts with each stroke. Gearboxes then drive the pumping action based on electric or pneumatic power. This achieves highly accurate volumes between 0.1 and 6 ounces.

Operators preset the target lubricant dosage on a control panel. Then, by pressing a button or lever, the electrically or air-powered lube meter delivers the exact amount of grease in one smooth motion. No manual pumping is required.

Advanced lube meters feature programmable timers and control boards to set custom dispense rates. Some models even tie into centralized lubrication systems covering entire plants. This allows monitoring and adjusting lube requirements from a central dashboard.

Using lube meters correctly ensures bearings get adequate lubricant – but not too much. Excess grease overpacks the housing, leading to overheating and premature seal failure from leakage. Undergreasing also causes excessive friction and wear.

To find the optimal grease volume, consult manufacturer specs for equipment bearings. Then, match this dosage to the lube meter output. For example, a 1⁄2 oz setting on a per-stroke meter would properly refill bearings needing 0.5 oz of grease every 100 hours.

It’s critical to use clean, filtered grease that matches viscosity recommendations. And don’t mix incompatible greases in the same housing. Improper lubricant selection leads to oxidation and lubrication breakdown.

Lube meters shine for preventative maintenance tasks like bearing regreasing. Workers don’t have to manually pump the exact amount, reducing human error and messy over-greasing. Metered lubricant keeps bearings operating optimally between major overhauls.

Lube meters efficiently regrease electric motor bearings based on runtime hours to prevent failure. Their precise grease metering matches manufacturer specifications for major motor components. This prevents under or over-greasing the housings.

Service centers use metered grease guns for ball joints, universal joints, and chassis lube jobs on customer vehicles. Accurate grease volumes improve job efficiency versus manual pumping while ensuring proper lubrication.

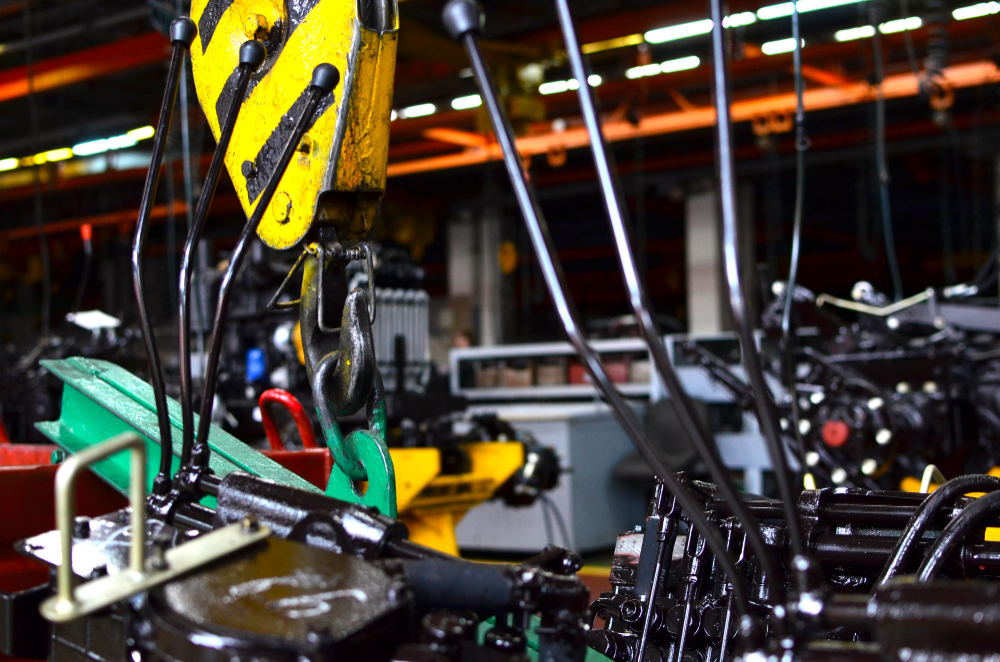

Manufacturing plants install automated lube metering systems on packaging equipment, conveyors, presses and other assembly line machinery. Centralized pumping stations deliver routine lubrication to all key components.

Lube meters also work for hinged doors, roll-up gates, hydraulic lifts, and other plant equipment with grease points. Convenient pumping stations located throughout large facilities make routine lubrication more efficient.

Lube meters accurately deliver the right oil and grease volumes for proper equipment lubrication. Electric and pneumatic options suit different industrial uses. With precise, clean lubricant dosing, lube meters optimize bearing and component life across manufacturing plants, facilities, and vehicle servicing bays.

See how Aocheng Group’s expertise in lubrication equipment can streamline maintenance routines. Our comprehensive lube meter and grease gun range provide unmatched accuracy and reliability.