We’ve used fuel dispenser pumps, but have you ever been curious about how they work? What’s the mechanism that makes them function the way they do? This article sheds light on the intricate workings of fuel dispenser pumps including their design and functionality. Fuel Dispenser Pump Basics Fuel dispenser pumps—also known as commercial fuel dispensing […]

We’ve used fuel dispenser pumps, but have you ever been curious about how they work? What’s the mechanism that makes them function the way they do?

This article sheds light on the intricate workings of fuel dispenser pumps including their design and functionality.

Fuel dispenser pumps—also known as commercial fuel dispensing pumps—are mechanical marvels designed to efficiently and accurately dispense fuel to various vehicles and equipment. They are often found in gas stations, truck stops, and other refueling points.

These pumps have evolved over the years to meet the increasing demands of a constantly evolving transportation landscape.

The Fuel Nozzle is the business end of the fuel dispenser pump, responsible for directing the fuel flow into the vehicle’s tank. It typically features a trigger mechanism for control and a spout for precise fuel delivery.

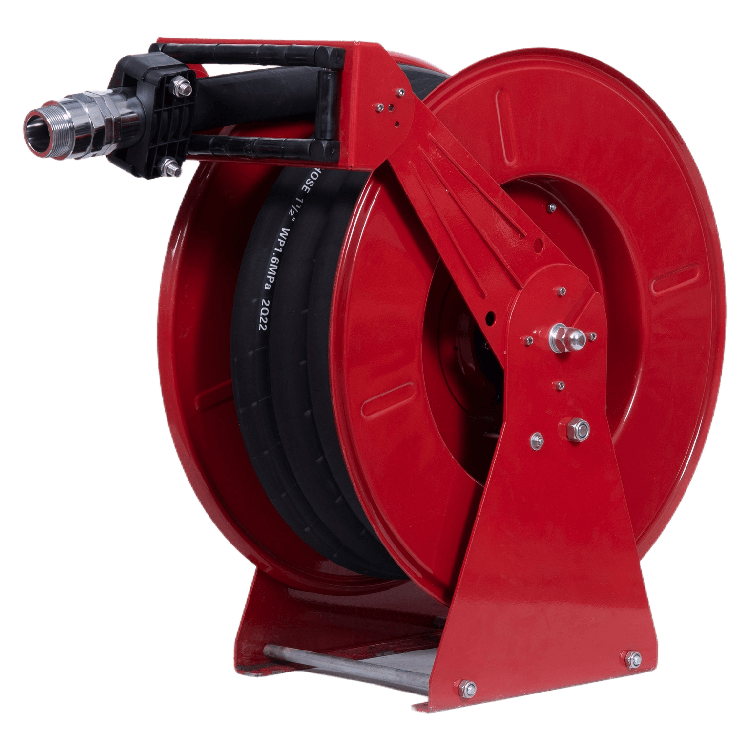

Connecting the nozzle to the pump, the fuel hose reel is a flexible conduit through which the fuel travels. It is designed to withstand the wear and tear of constant usage and must be durable and resistant to fuel and environmental factors.

Precision is paramount when it comes to dispensing fuel. The fuel flow meter, a critical component of the pump, accurately measures the amount of fuel passing through, ensuring customers receive the correct quantity.

The pump unit is the powerhouse of the fuel dispenser pump. It draws fuel from the underground storage tank and propels it through the system for dispensing. Various types of pumps, including submersible and suction pumps, are used in commercial fuel dispensing pumps.

Modern fuel dispenser pumps are equipped with sophisticated Fuel Management Systems. These systems manage the entire fueling process, from authorizing the transaction to monitoring fuel levels and generating receipts.

Explore Our Fuel Dispenser Solutions>>>

The operation of a fuel dispenser pump involves a series of carefully orchestrated steps to ensure a seamless and safe fueling experience.

Before fuel dispensing begins, the customer must authorize the transaction. This is typically done through payment methods such as credit cards, debit cards, or mobile payment systems. The electronic control system verifies the payment and releases the nozzle for fueling.

If the fuel station offers multiple grades of fuel, the customer can select the desired grade using the controls on the dispenser. This choice is communicated to the pump unit, ensuring the correct type of fuel is dispensed.

Once authorized and the fuel grade selected, the customer can lift the nozzle from its holster. This action triggers the electronic control system to activate the pump unit and initiate the flow of fuel.

As the fuel flows through the hose, the meter accurately measures the quantity dispensed. The electronic control system continuously monitors the process to prevent overfilling and to stop dispensing when the desired quantity is reached.

Most modern fuel dispenser pumps are equipped with an automatic shut-off mechanism. This ensures that the fueling process halts automatically when the tank is full to prevent spills.

Upon completion of the fueling process, the electronic control system finalizes the transaction. It generates a receipt and updates the fuel inventory, keeping track of the quantity dispensed and available stock.

An emergency stop button is often installed on the dispenser for immediate cessation of fuel flow in case of any unforeseen circumstances or malfunctions.

To minimize the risk of static electricity sparking a fire, fuel dispenser pumps are equipped with anti-static devices, grounding the system and dissipating any build-up of static charge.

The intricate design and precision engineering of fuel dispenser pumps contribute to the seamless and efficient fueling experience we often take for granted.

Next time you fill up your tank, take a moment to appreciate the mechanical symphony behind the fuel dispenser pump that keeps our vehicles running and industries thriving.

If you’re looking for quality fuel dispenser pumps, visit our website or get in touch with us.